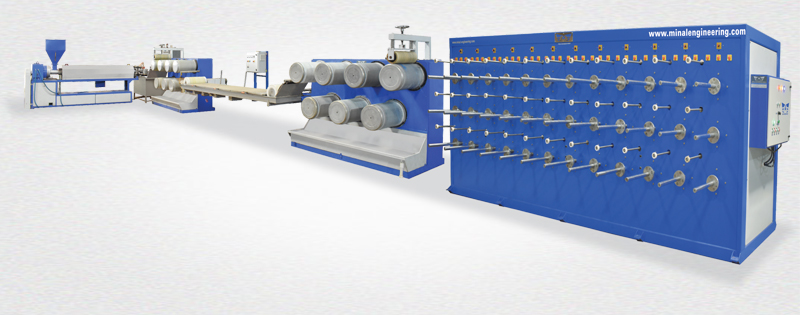

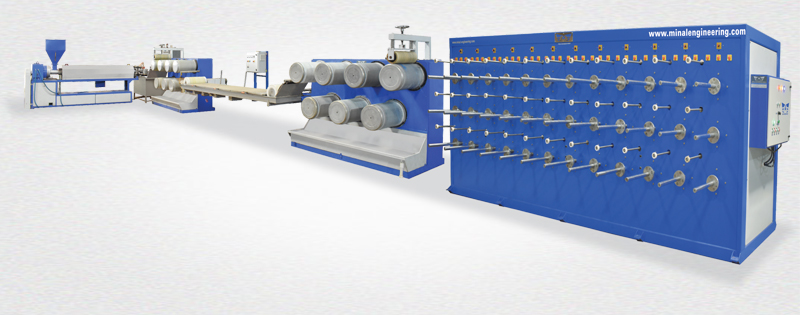

Monofilament Rope Yarn Extrusion Line / PP Fibrillated Tape / Dunline Monofilament Line

| Models |

65 mm / 75 mm / 85 mm / 90 mm |

| Godet Options |

5 / 7 Pulley |

| Winder Station |

8 to 36 Station Bobbin Winder |

| Winding Option |

Metal Bobbin / ABS Bobbin |

| Line Speed |

100 – 180 MPM* |

| Connecting Load |

75 – 175 Kw * |

| Production Capacity |

75 – 150 Kg/hr* |

- Bunch Filament Yarn Winding

- T-Die For Fibrillated Tape Plant

- Joint Filament Yarn & Flat Yarn For PP Dunline

- Hot Air Oven Stretching Unit for PP Yarn

- Advance Digital Controlling System

- Auto Synchronized Mechanism

- Auto Interlocking mechanism

- Power Consumption Meter to Convert Cost of Production

- Ampere Monitoring System

- Smooth & Noise less Performance

- Safety Sensor with Warning Lights & Alert Siren

- High Power Efficiency

- Linear Heating & Power Saver Invertor type heat controller

- Heavy Duty Body Structure for Less Vibration

- Online Production Monitoring System

- Computer Based Touch Screen & Wifi Module

- Melt Pump & Auto Speed feed Back Unit

- Online Pressure sensor Monitoring System

- Multiple Program Saving Unit

- Hot Air Oven

- Fibrillating Unit

- Wi-Fi / LAN Connection for Online Monitoring of Plant Performance

- Shipping & Marine Industry Rope

- Transportation Rope

- House Hold Ropes

- Construction & Building Safety Net

- Recreational Activity Equipments

- Sports Net